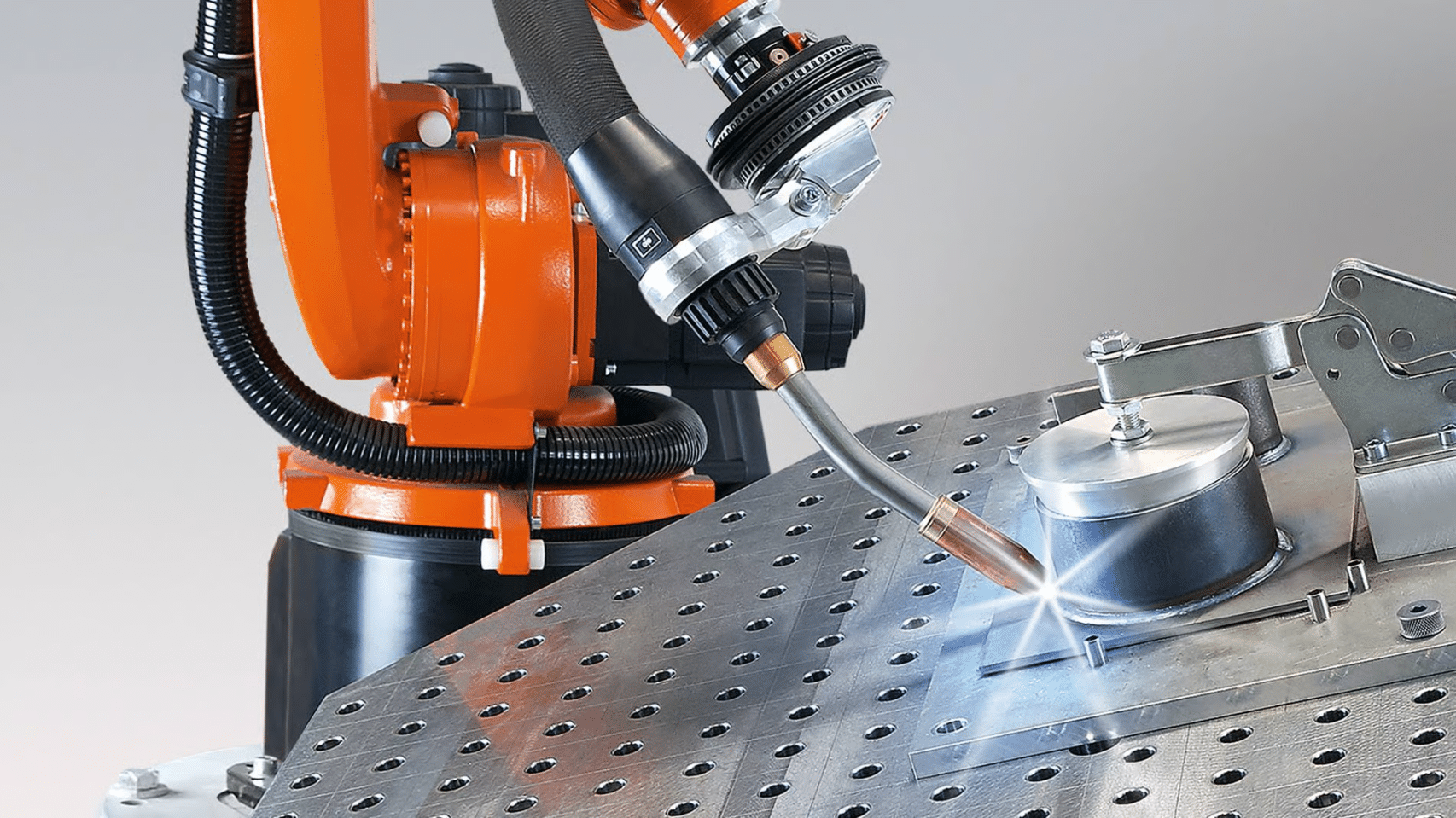

Welding Robot

The welding robot is equipped welding torch that uses Euroconnector, by which the robot can work together with all welders up to 200 Amps.

Hanwha HCR-5A

Arm

- Payload: 5Kg

- Reach: 915mm

- Weight: 21kg

Performance

- Max. linear TCP speed: 1.5m/s

- Repeatability: ±0,05mm

- Operating temperature: 0-50°C

- I/O ports: 4 DI/4DO/4AI/0AO

- I/O power supply: 24V & 3A / 24V & 1,5A

Other Features

- IP classification: IP54

- Noise level 65dB

- Mounting direction: All direction

Control Box

- I/O Ports: 16 DI/16DO/2AI/2AO

- I/O power supply: 24V

- Weight: 17.6kg

- Communication: TCP/IP, Modbus TCP, Profinet, Ethernet/IP

- Supply Voltage: 100-240 VAC

- IP classification: IP20

The Hanwha HCR-5A is part of Hanwha’s upgraded A-series cobots. This series of Hanwha cobots is characterised by three things: ease of use, flexibility, and safety in operation.

The HCR-5A cobot is extremely easy to operate: For most applications, the operator can be trained in just one day. It is also designed to be quickly deployed from one station or process to another. This is made possible by its user-friendly software and intuitive user interface. As processes and materials change, the Hanwha Cobot is designed to change with them.

In addition, the A-Series cobots are designed from the ground up with safety in mind. They can work in close cooperation with employees while they are in operation. The HCR-5A has proven itself in machine tending, welding, automotive and many other applications.

The HCR-5A in particular has been significantly upgraded compared to the original HCR-5. The linear speed has been increased to a maximum of 1.5 m/s.